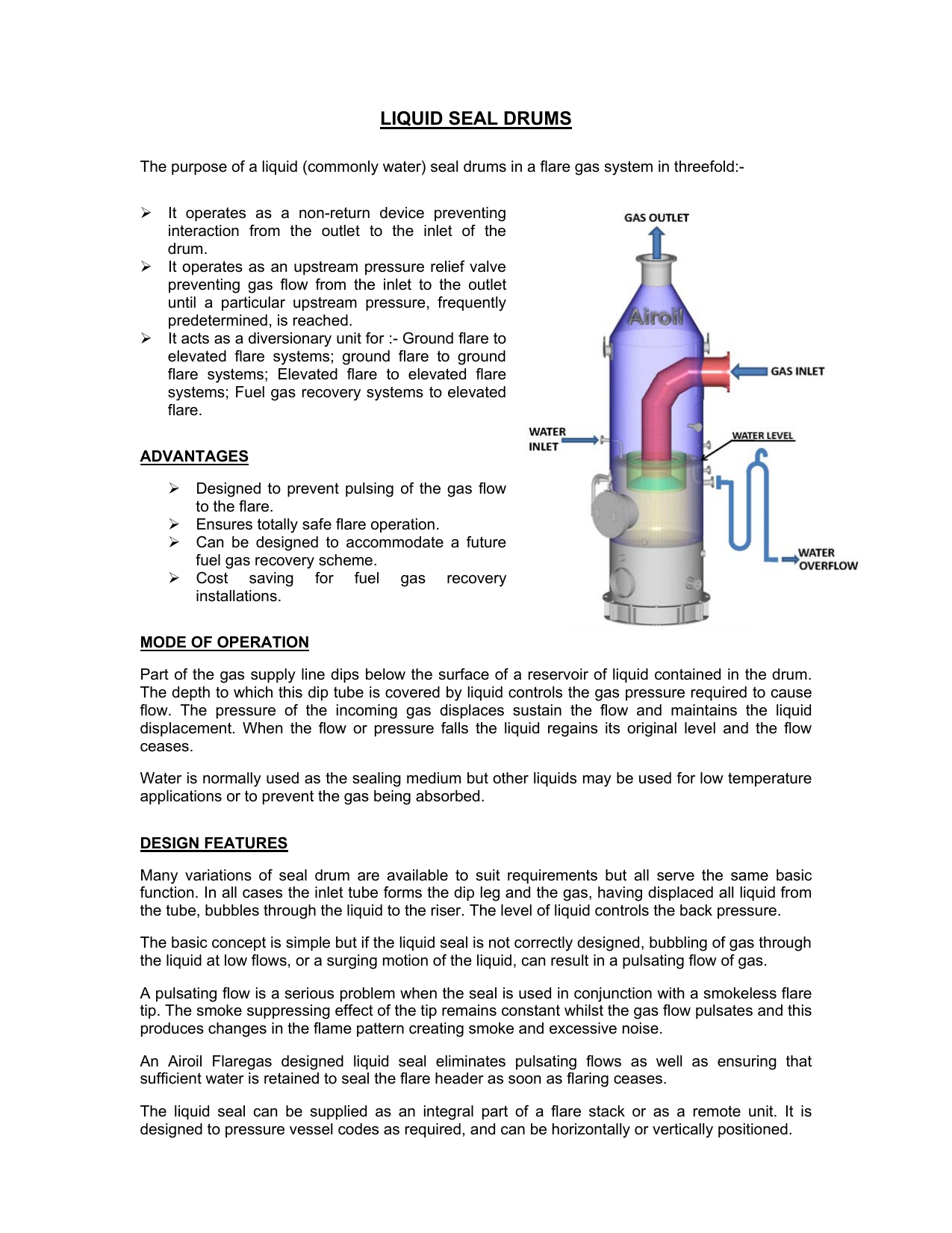

This creates a situation where the condensate. Tanks Blanketed with Inert Gas Liquid Seal Leg In this design the take-off point for the overfill drain is at the location of the maximum allowable fill level for the tank.

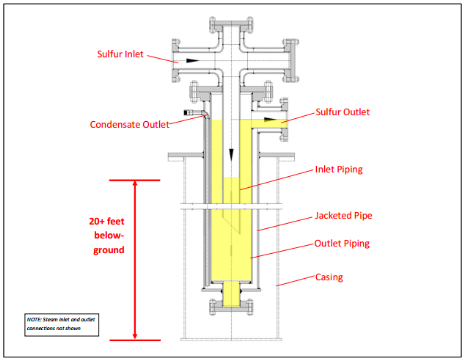

Sulfur Unit Sulfur Sealing Options Part 1 Brief Overview Of In Ground Sulfur Sealing

Additionally the leg seal will serve as an additional guards for the leg pin.

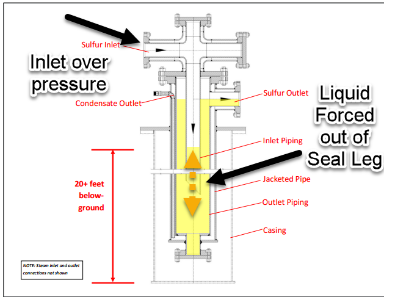

. DESIGN FEATURES Many variations of seal drum are available to suit requirements but all serve the same basic function. I like to design the down leg for self. The liquid discharge is.

I think you will find some useful information on seal legs there. Buffer fluid is circulated between the inner and outer seal chamber. Seal liquid and the gland cooling is normally used.

Flex Seal Liquid Black 32 Oz. However it does identify concerns that are associat-ed with seal welding and the galvanizing practice. The difference between the underflow seal leg height H 1 and the overflow height H 2 creates a static pressure that must be balanced by the liquid column in the drumBecause the H 2-height column contains all heavy liquid and thus differs in density from the average density in the H 1-height column the interface between the heavy phase and light phase varies.

The first leg seals are in service for well over 25 years in service and are still in excellent condition. Liquid-acid vaporizes and expands when the part is dipped into the hot zinc. FLEX SEAL FAMILY OF PRODUCTS Flex Tape Black 4 in.

The mudgas separator controls gas cutting during kick. This traditional device has been utilized in SRUs for over 50 years. In turbulent operation such as occurs with frequent operation or mixing the leg pin may get loose and drop out of the sleeve.

Figure 9 Figure 9 Liquid Sulphur ViscosityLiquid Sulphur Viscosity Liquid Sulphur Viscosity 0001 0010 0100 1000 10000 100000. If mechanical seals are employed a supply of cooling and flush. HOTWELL DESIGN The designer must carefully consider open hotwell design in a process Figure 3.

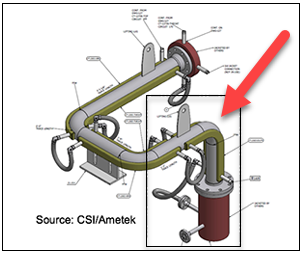

A seal leg used in a piping system is a vent pipe that functions as a wayto control the fluid Continue Reading Skip to content 1 713 731-0030 Toll Free. A liquid seal leg is placed at the end of the discharge line located at or below grade. The second type is an above-ground sulfur sealing unit.

How can I determine the minimum height of the seal leg. Use of sulphur seal legs Improvement in lookbox design Elimination of lookboxes Exposure to Molten Sulphur Proper tracing and steam supply Packing glands for rod-out connections. Dear SirMadam Sorry to bother you this trivial.

The condensate form in these three horizontal condensers and drained directly to the storage tank. In vacuum pump system design pre-condensers should be considered if a large part of the gas load is condensable. The first type is an in-ground sealing device that is commonly referred to as a sulfur seal leg.

Effective for overfilling cases. The leg seal will prevent the. Can be routed to a closed system or designed with a liquid seal.

During normal operation liquid. Valuable hydrocarbons or water are common constituents in oil and gas downstream processes. As indicated in figure-1 liquid seal at the flare stack base is essentially a cylindrical volume of liquid into which the gas inlet to flare stack is dipped.

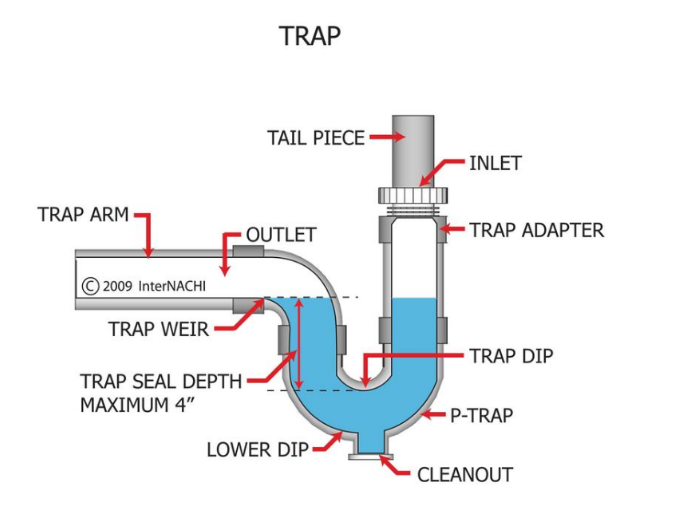

Simple design similar to a free vent. In all cases the inlet tube forms the dip leg and the gas having displaced all liquid from the tube bubbles. In a vacuum system that is used to condense steam and condensable vapors through heat exchangers or condensers the condensate is normally dropped into a receiver tank that is often vented to atmosphere or a low-pressure vent system.

A barometric leg is basically a condensate drain. Liquid Rubber Sealant Coating. In this design seal liquid is taken directly from a main and supplied to the pump Figure 1.

Small amounts of entrained gas can then be handled by a vacuum-type degasser located in the mud pits. Our SxSeal 1000 and SxSeal 2000 are two perfect examples of above-ground devices. Multiple seal arrangements are used to isolate toxic gases and fluids that can change state when exposed to the atmosphere.

Liquid seal leg design Written By millardgradwohl26273 Tuesday March 29 2022 Add Comment Edit This is how the Greeks make roast lamb cooked until tender half braised in a garlic lemon flavoured liquid that transforms into a luscious sauce no mucking around with gravy. This edition of Design File is not intended to be a treatise on galvanizing and preferred details for corrosion resist-ance. 10 of the mechanical seal Shaftshaft sleeve diameters are always three-digit numbers beneath the stationary seat for types U and B Seal face Stationary seat Secondary seals Spring Other metal parts except seal cover and shaft sleeve Direction of rotation of the mechanical seal Type N and K Type C is also the spring winding direction R.

The liquid in the tailpipe is known the height should be adjusted accordingly. Piping configuration may contribute to too much backpressure to provide effective vapor relief. Strong Rubberized Waterproof Tape.

Good practice recom-mends that the hotwell area be equal to 15 times the tailpipe volume measured from the bot-tom of the tailpipe to the point of overflow not less. Liquid seal volume does not permit any air flow entering the gas inlet. How Customized Seal Support Systems Work.

The seal leg has to be set up to prevent the siphoning of liquid from the seal loop. Venting minimizes that concern. LIQUID SEAL DRUMS The purpose of a liquid commonly water seal drums in a flare gas system in threefold-.

Minimum Siphoning Seal Leg Height - posted in Industrial Professionals. A barometric leg is basically a condensate drain that consists of a leg pipe between the pre-condenser and the hotwell. A non-pressurized external reservoir system acts as a protective buffer between the product and the atmosphere.

Potential static discharge if liquid is subjected to a significant free-fall distance. Aerosol Liquid Rubber Sealant Coating Black. This volume allows the flow of flared gas from inlet pipe to the stack in form of bubbles rising through the liquid.

The mudgas separator poor boy degasser is designed to provide effective separation of the mud and gas circulated from the well by venting the gas and returning the mud to the mud pits. This type of overflow line is suitable for the case where it is. Seal legs katmar Chemical 25 May 10 0100.

FLEX SEAL FAMILY OF PRODUCTS 14 oz.

Liquid Seal An Overview Sciencedirect Topics

Sulfur Unit Sulfur Sealing Options Part 1 Brief Overview Of In Ground Sulfur Sealing

Liquid Seal An Overview Sciencedirect Topics

Sulfur Unit Sulfur Sealing Options Part 1 Brief Overview Of In Ground Sulfur Sealing

Sulfur Unit Sulfur Sealing Options Part 1 Brief Overview Of In Ground Sulfur Sealing

0 comments

Post a Comment